-

About UsProductsCustomized SolutionProjectGalleryNews

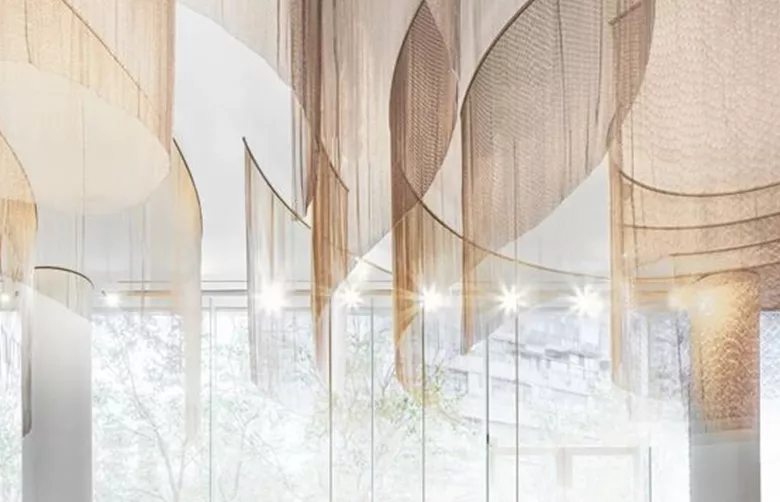

Woven metal interior in elevator design

Release time: January 15, 2024In addition to their aesthetic appeal, architectural woven metal interiors used in elevator design offer practical benefits that make them a versatile and durable choice. Their durability, longevity, and relatively low-maintenance requirements make them a cost-effective solution for elevator owners and operators.

Architectural woven metal mesh is typically made from high-quality materials such as stainless steel or aluminum, which have excellent corrosion resistance and are highly durable. This ensures that the mesh will withstand the wear and tear associated with regular use in elevators and remain in good condition for a long time.

The inherent strength of metal mesh makes it suitable for high-end, high-traffic environments where there is a lot of foot traffic and use. The mesh is able to handle the frequent impact and stress without damage, maintaining its structural integrity over time.

Architectural woven metal mesh also requires relatively low maintenance compared to other materials commonly used in elevator design. It is generally cleanable and easy to maintain, reducing the need for regular replacement or significant repairs. This low-maintenance aspect can save time and money for elevator owners and operators, as they do not have to dedicate resources to regular upkeep or replacement.

In addition to its practical benefits, the durability and longevity of architectural woven metal mesh also contribute to its sustainability credentials. It has a longer lifespan than many other materials used in elevator design, reducing the need for frequent replacement and the associated environmental impact.

In conclusion, architectural woven metal interiors used in elevator design offer not only aesthetic appeal but also practical benefits that make them a versatile and durable choice. Their durability, longevity, corrosion resistance, and low-maintenance requirements make them an excellent option for elevator owners and operators seeking a cost-effective and sustainable solution.

Recommended News