-

About UsProductsCustomized SolutionProjectGalleryNews

Decorative metal woven fabric materials, weaving methods and precautions for use

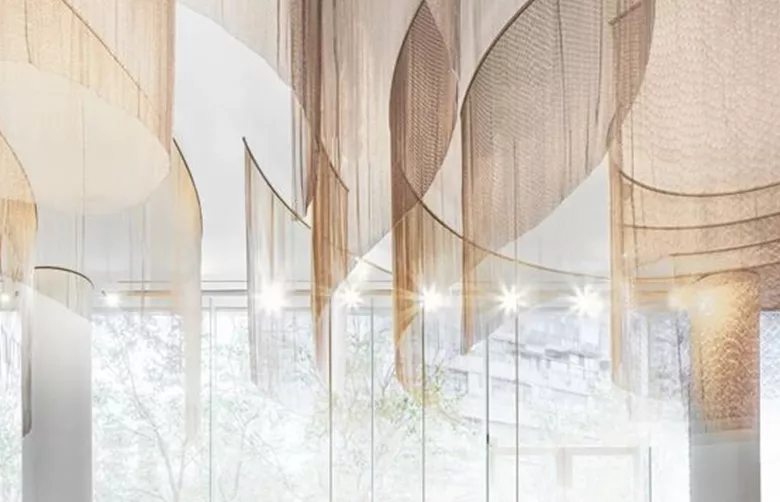

Release time: November 27, 2024Decorative metal woven fabric is indeed a popular material. It is not only beautiful, but also durable and suitable for a variety of decorative scenes. The following is a detailed introduction to the material, weaving method and precautions of metal woven fabric:

1. Material of metal woven fabric

Metal woven fabric is a product that combines metal wire and fabric. The common metal wire materials are mainly the following:

Stainless steel: woven from stainless steel wire, it has excellent corrosion resistance and high temperature resistance. It is widely used in chemical, petroleum, pharmaceutical and other industries. It is also often used in decorative woven fabrics to increase its durability and texture.

Copper: woven from copper wire, it has good electrical conductivity and beauty, and is often used in decoration and shielding fields. Fabrics woven from copper wire can show a unique metallic luster under light, which is very suitable for interior decoration.

Aluminum: woven from aluminum wire, it has the characteristics of light weight and good thermal conductivity. It is often used in air filtration and insulation fields, and is also suitable for some decorative scenes that require lightness and beauty.

Nickel: Woven from nickel wire, it has excellent high temperature resistance and corrosion resistance. It is often used in aerospace, chemical industry and other fields. It is also used in decorative woven fabrics because of its unique metallic texture.

Alloy: Woven from alloy wires composed of different metal elements, it has good comprehensive performance and wide application. Fabrics woven from alloy wires can achieve a high level in strength and beauty.

2. Precautions for the use of metal woven fabrics

Cutting: When cutting metal woven fabrics, special cutting tools such as metal shears or laser cutting machines should be used to ensure that the cutting edges are neat and will not damage the fabric. Avoid using inappropriate tools for cutting to avoid damaging the fabric or causing safety hazards.

Laying and installation: When laying and installing metal woven fabrics, ensure that the surface is flat and there are no sharp objects or hard objects protruding to avoid damaging the fabric. At the same time, care should be taken to avoid contact between metal woven fabrics and corrosive substances to avoid chemical reactions that may damage the fabric.

Cleaning and maintenance: Metal woven fabrics should be kept clean during use to avoid dust, oil and other pollutants from adhering to the surface. Wipe the surface regularly with a soft dry cloth to maintain its gloss and extend its service life. If cleaning is required, use a mild detergent and a soft brush, and avoid using corrosive cleaning agents such as bleach or strong acids and alkalis.

Safe use: Metal woven fabric has a certain conductive property, so during use, care should be taken to avoid direct contact with power supplies or electrical equipment to avoid electric shock accidents. At the same time, during storage and transportation, it should also be avoided from being squeezed with sharp objects or heavy objects to avoid damaging the fabric or causing safety hazards.

In summary, decorative metal woven fabrics have received widespread attention and application for their unique metallic texture and beauty. When using, attention should be paid to choosing the right material and cutting tools, keeping the surface flat and clean, avoiding contact with corrosive substances, and paying attention to safety issues.

Recommended News